New Flushing principle

This blog post describes a new flushing principle Available at location? that was introduced in Dynamics 365 for finance and operations, Enterprise edition for the spring release 2017.

The flushing principles reflect different consumption strategies for raw materials that are used in production processes. Consumption is the process that deducts material from the on-hand inventory and sets the value of the consumed materials to Work in progress (WIP) for production orders and batch orders. Raw materials are usually consumed from a location that is configured for the process that consumes the material. This location is known as the production input location. Material consumption for production and batch orders is accounted for in the Production picking list journal.

Flushing principle available at location

The Available at location flushing principle indicates that the material will be automatically consumed when it's registered as picked for production. The material is registered as picked from location when work for the raw material picking is completed, or when material is available on the production input location and the material line is released to the warehouse. The picking list that is generated during the process is posted in a batch job. This principle is relevant if, for example, you have many picking activities against one production order. In this case, you don't have to update the picking list manually, and you can get a current view of the WIP balance.

Let's walk through some simple scenarios that shows how the new flushing principle works.

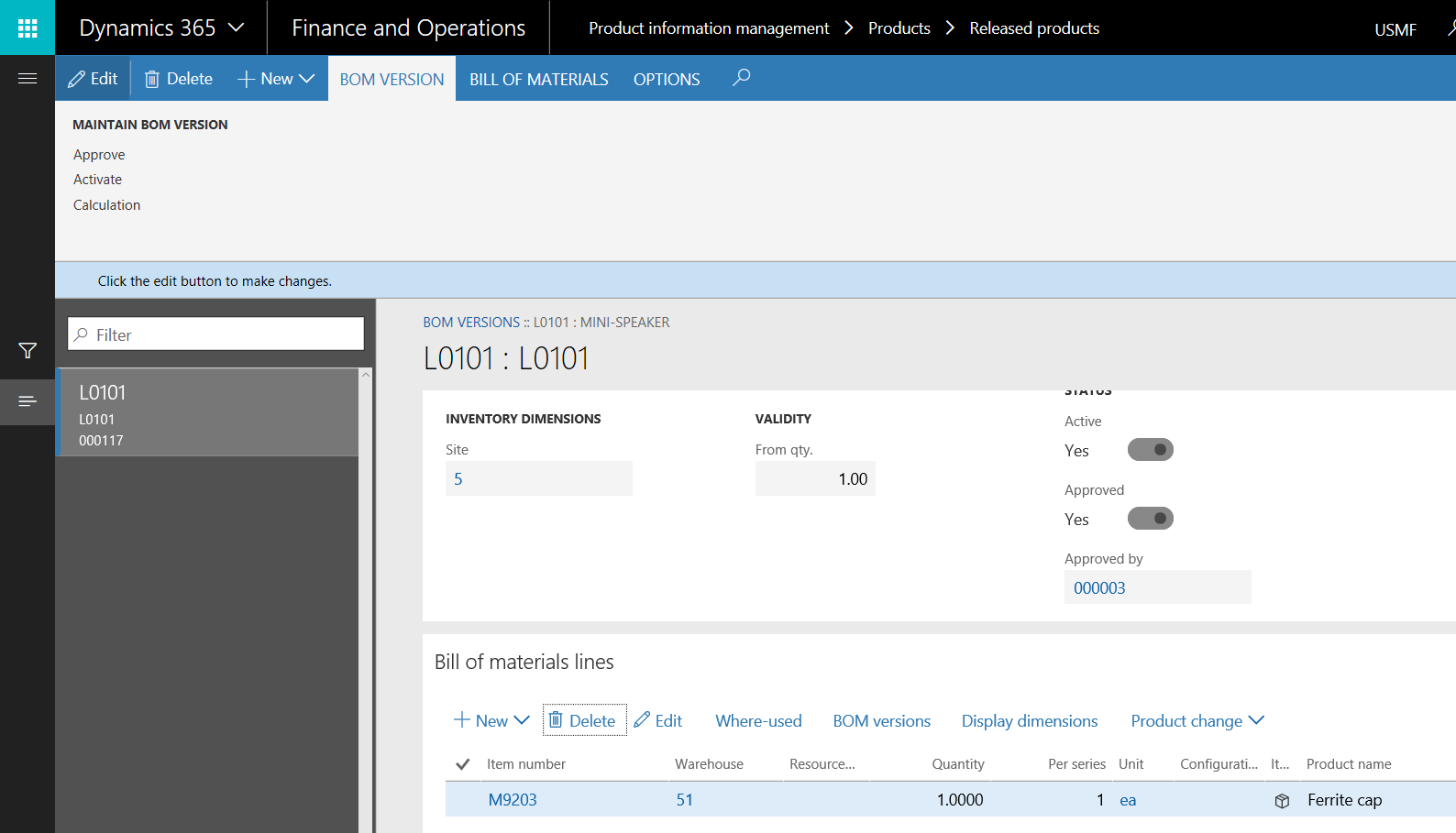

In the following example we will be using product L0101 from the USMF demo data.

- Go to the BOM version for L0101 and remove product L0100 and M9204, so the resulting bill of material looks like below.

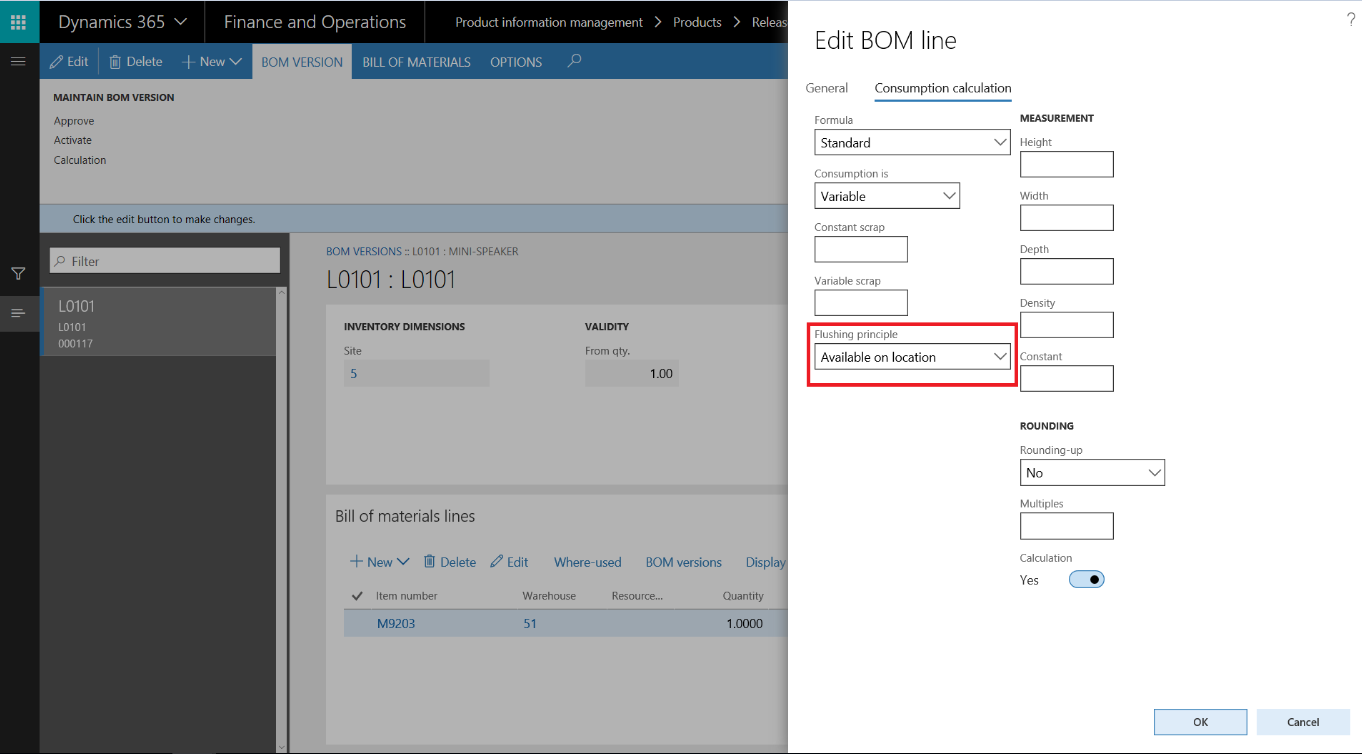

2. Go to the details for the line item for M9203 and change the flushing principle to “Available at location”

3. Create a production order for L0101 with the default quantity 20.

4. Estimate and Release the production order

a. Verify that work has been created for M9203

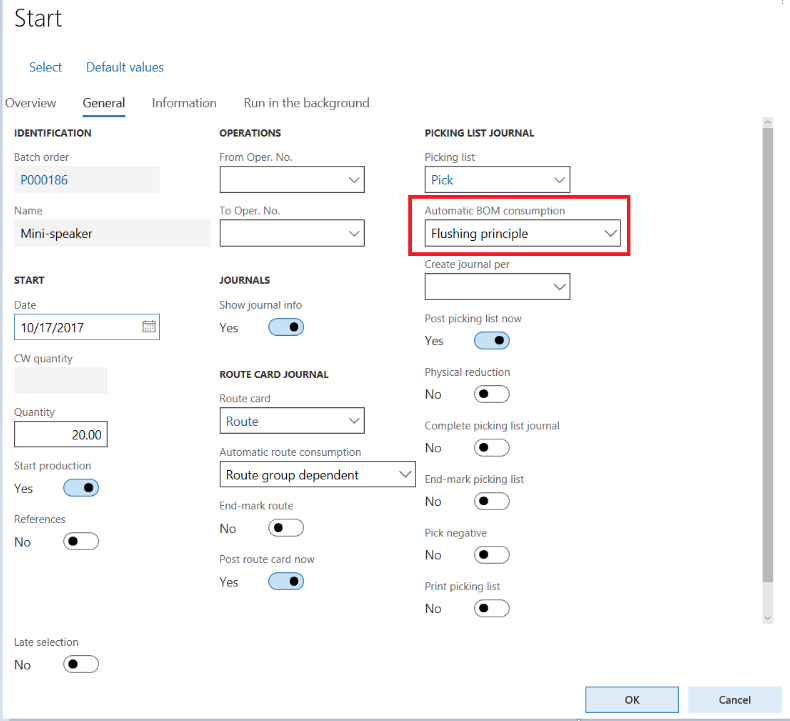

5. Start the production order with the below setting

Note: When starting the production order, no picking list was created. This is because no material has yet been made available on the production input location by completion of warehouse work.

6. Process the warehouse work with the help of the hand-held device

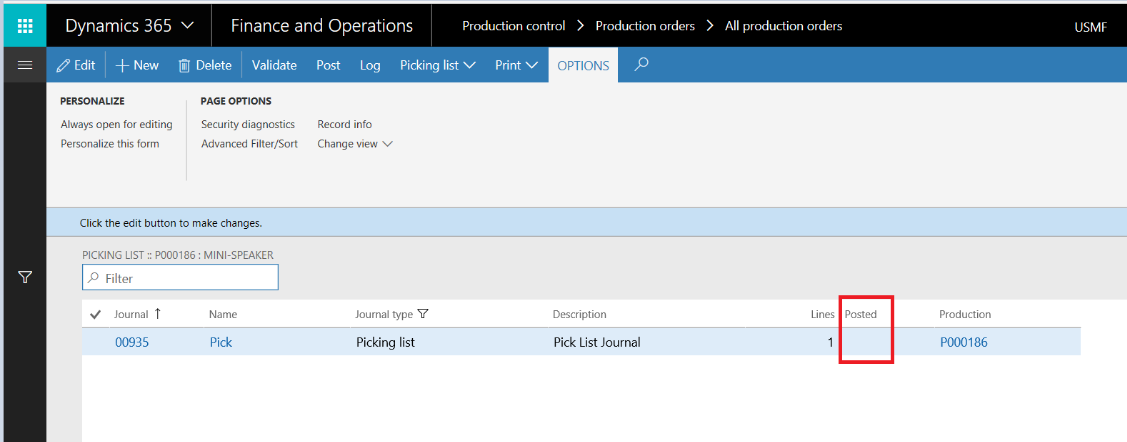

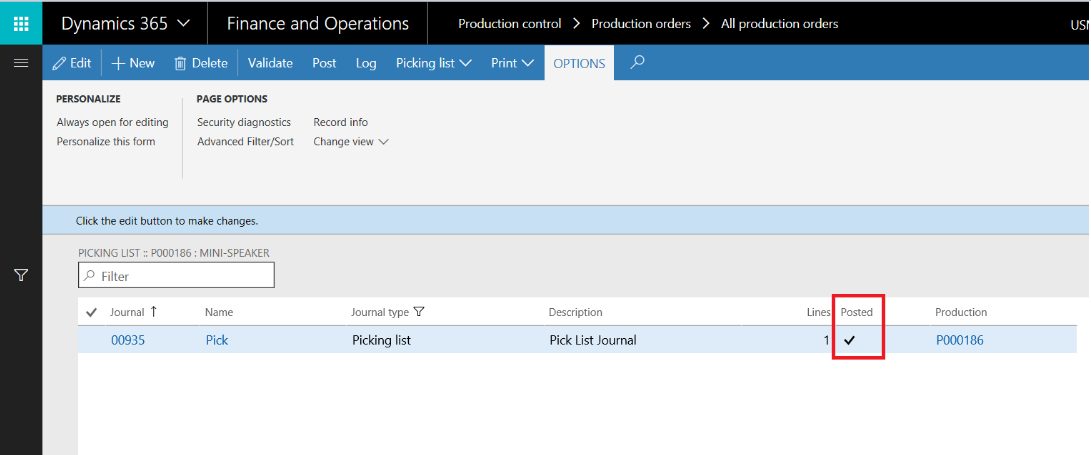

7. After completing the work, go to the picking list of the production order

Note: Because the bom line has the flushing principle Available at location the picking list journal was automatically created when the pick work was completed. The posting of the picking list is inserted into a batch job, and that is why it can appear as not posted when opened just after the work is completed. After a couple of minutes after work completion the picking list will be posted by the batch job.

8. Create a new production order for L0101

9. Estimate and Release the order

Note: No work was created, because M9203 is available at the production input location, because we staged the full quantity of the license plate (200 pcs) when we processed the work for the first production order and we only consumed 20 pcs, so 180 pcs are remaining.

10. Start the production order with Auto BOM Consumption = Flushing principle

Note: A production picking list was created and posted. When material is already available at the production input location, the flushing principle “Available at location” has the same behavior as the flushing principle “Start”.

Comments

- Anonymous

October 17, 2017

Hi Johan, is there any means to affect the recurrence / selection criteria of the batch job that posts the picking list journals? I can't seem to find it anywhere in Production, Whse Management, or Sys Admin modules.- Anonymous

October 26, 2017

Hi Colby,The posting of the picking list is batch job, but not recurrent. The batch job is automatically created as part of completing the put transaction of the work. You should be able to find the batch job in the batch queue.Best regards,Johan

- Anonymous

- Anonymous

October 20, 2017

Hi Johan,Nice blog, thanks for sharing. Seems like interesting functionality! Does the "Issue status after raw material picking" warehouse parameter have any influence on the flushing process?- Anonymous

October 26, 2017

Hi Wayne,The Issue status after picking parameter on the warehouse does not affect the scenario.Best Regards,Johan

- Anonymous

- Anonymous

November 11, 2017

Hi Johan, Thx for a nice post. Have you tried the process where part of the needed quantity is available at the production input location and part of it needs to be moved from a raw material location. When proceeeding this, we are not able to complete the created raw material work. Example: Quantity needed: 100, 50 available on Production input location. Then work is created for 50 from. We get an error message when completing the put-step. Seems as if there are two lines created for the picking list, which may cause the trouble? Any ideas?Thanks- Anonymous

November 14, 2017

Hi Niklas,The expected result in this case should be that the quantity on the input location should be picked and pick work should be created fro the remaining quantity. One question: Did you create an open production pick list, before processing the work. In that case you run into this issue when completing the put-step of the work. The only work around in this case is to delete the pick list, then process the work and then re-create the pick list. This is of course far from optimal. We are in process of fixing this issue, so the pick work can be completed when an open pick list exists. This fix will be part of D365 next release.Best regards,Johan

- Anonymous